- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

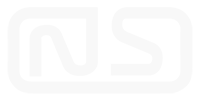

Automatic Hot And Cold Laminating Machine

Send Inquiry PDF DownLoad

We assure you of our high quality services at all time. Automatic hot and cold laminating machine is widely used in all kinds of high-grade and a variety of prints. NEW STAR is a Automatic hot and cold laminating machine manufacturer to some of the world’s leading brands. We offers a complete range of machine manufacturing services. 12 years of experience, Cutting-edge technology.

Automatic hot and cold laminating machine

Automatic hot and cold laminating machine is an intelligent equipment with a high degree of automation and high efficiency and energy saving (power consumption is about 15 degrees per hour). The machine is fully functional, adopts humanized design, adopts PLC centralized control, and automatically detects faults. And automatically make corresponding treatments, the drying system adopts a hot air circulation system, combined with an active follow-up drying and heating device, which improves the drying efficiency of acceleration and deceleration, and greatly improves the control performance of the whole machine.The operation with the man-machine interface is more intelligent and humane. It is composed of a high-speed paper feeder, a powder remover, a laminating and coating device, a finished product break and a paper take-up machine.

Product Parameter (Specification)

|

Model |

FH-1080 |

|

Max paper size |

1080*1200mm |

|

Min paper size |

300*270mm |

|

Paper weight |

80-500g/m2 |

|

Laminating speed |

12000pcs/h |

|

Feeder Height |

1200mm |

|

Electricity |

15kw/hour |

|

Power |

65kw |

|

Total weight |

7000kg |

|

Overall dimension |

9308*2100*2920mm |

Product Feature And Application

FH fully Automatic hot and cold laminating machine as a professional equipment used for plastic film laminating on the surface of paper printed matter. Widely applicable for laminating in packaging, paper box, books, magazines, calendars, and commercial cards fields, Improving the printing matter grades, and achieve the purpose of dustproof, waterproof, oil proof. it’s the best choice for printing and laminating enterprises of all scales.

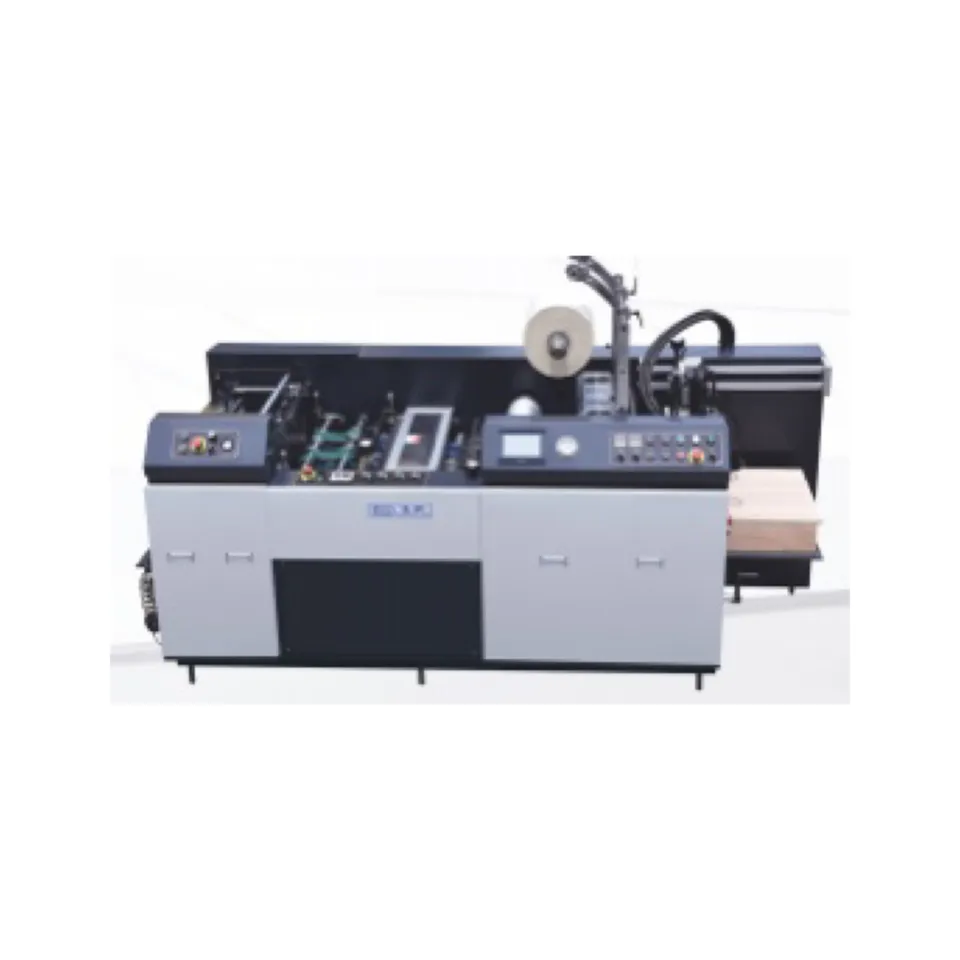

1. High-speed paper feeder and automatic stacker

2. Equipped with vertical and horizontal positioning mechanism

3. Using servo technology,PLC control and centralized control of human-computer interaction system

4. The paper setting is controlled within±2mm

5. Oil-free vacuum pump

6. Paper pile detectio nmechanism,paper out detection mechanism and other series of sensor detection mechanism

7. The whole machine adopts high-precision synchronous belt and part of imported chain transmission

8. 380mm composite heating roller,matching electromagnetic variable power heating system

9. 8320mm imported silicone pressure roller,with good temperature and pressure resistance and non-stick performance

10. 800mm drying heat roller,made of industrial non-stick material Teflon coating

11. The drying system adopts a hot air circulation system,combined with an active follow-up drying and heating device

12. Adopt active follow-up shearing technology for slitting

13. Equipped with disc knife cut

14. Using the whole machine centralized control system to realize precise pneumatic breaking

15. Auxiliary suction and buffer system

16. Equipped with wave pressure device,matching pneumatic automatic paper making

17. Load automatic waste rejection device

18. Match the paper jam detection system to realize intelligent deceleration

19. (Optional)Servo intelligent plate change without manual care.

Product Details

|

High speed automatic paper feeding system |

High precision lays |

|

|

|

|

Powder cleaning unit |

Eletromagnetic heating |

|

|

|

|

Laminating section |

Disc throwing knife mechanism |

|

|

|

|

Auto slitting mechanism |

Collecting system |

|

|

|

|

Feeder transmission |

Main motor |

|

|

|