- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

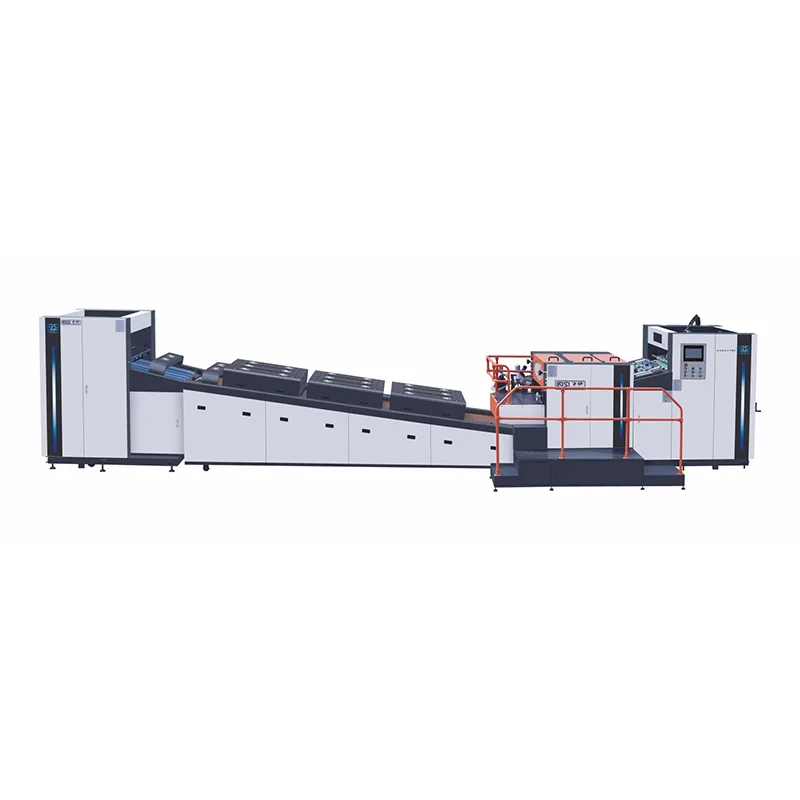

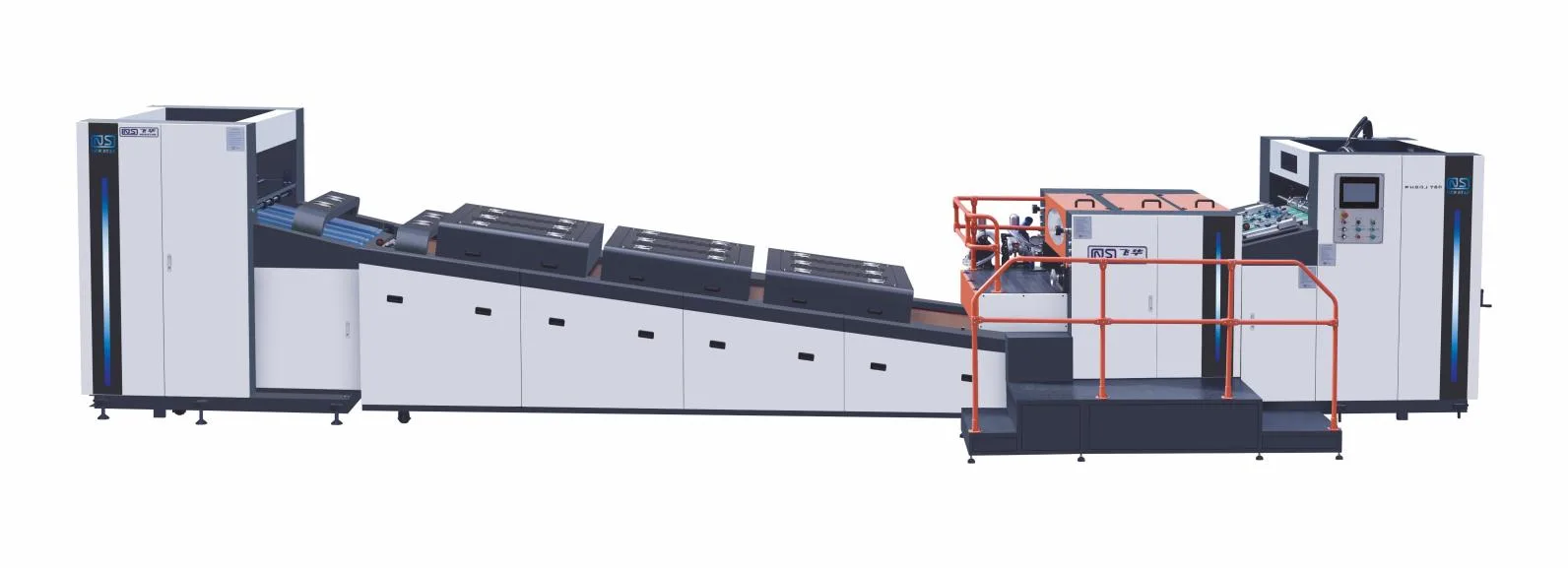

FHSGJ-760 Full Automatic High-speed Full Spot Varnish Machine

We've focused on improving speed and precision. As a leading Chinese manufacturer, we strive for greater efficiency and problem-solving.

Send Inquiry

Scope of application

TNEW STAR FHSGJ-760 Full Automatic high-speed full/spot Varnish Machine launched by our company, which can improve the printing properties: waterproof, dustproof, surface beautification, etc. It is suitable for posters, books, brochures, color boxes, color box packaging, etc. Varnishing process!

Technical parameters

|

Model |

FHSGJ-760 |

|

Max.Sheet Size |

760*730mm |

|

Min.Sheet Size |

290*290mm |

|

Paper thickness |

80~500g/m2 |

|

Laminating speed |

9000sph |

|

Voltage |

380V 50HZ |

|

accuracy |

±0.2mm |

|

Power |

42kw |

|

Total weight |

6500kg |

|

Overall Dimensions |

9200*1650*1900mm |

|

UV Lamp |

3*8KW |

|

IR Lamp |

18*1.5KW |

Detail configuration

(1) Standard machine structure

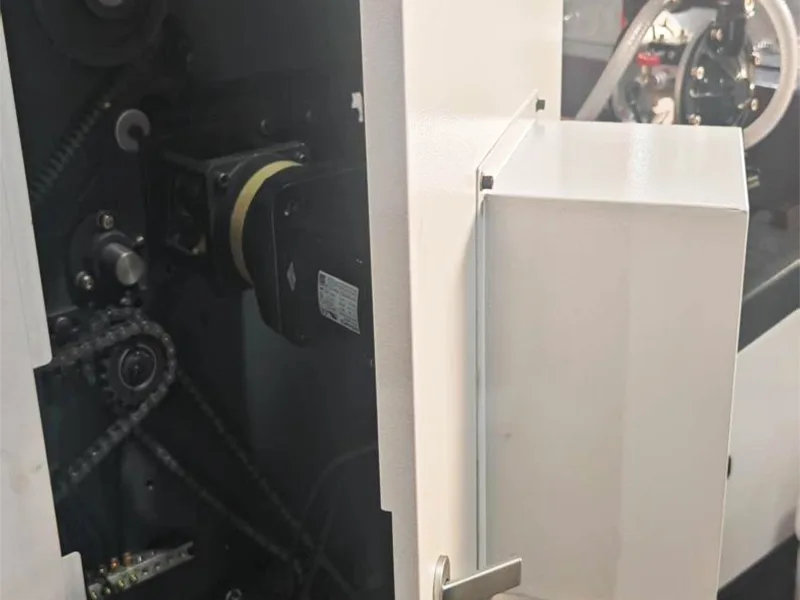

1. Automatic feeder

2. Coating unit (UV oil/Water-based glossy oil)

3. Drying conveyor system( UV dryer/IR dryer)

4. Automatic stacker

5.Automatic control system

(2) Machine configuration and technical specification

1. Automatic paper feeder

- High reliability is adopted for fast and smooth paper feeding.

- Equipped with sensitive electromechanical double-tension detector and foreign body baffle, the machine will stop immediately if abnormal.

- Accurate and reliable front gauge and side gauge.

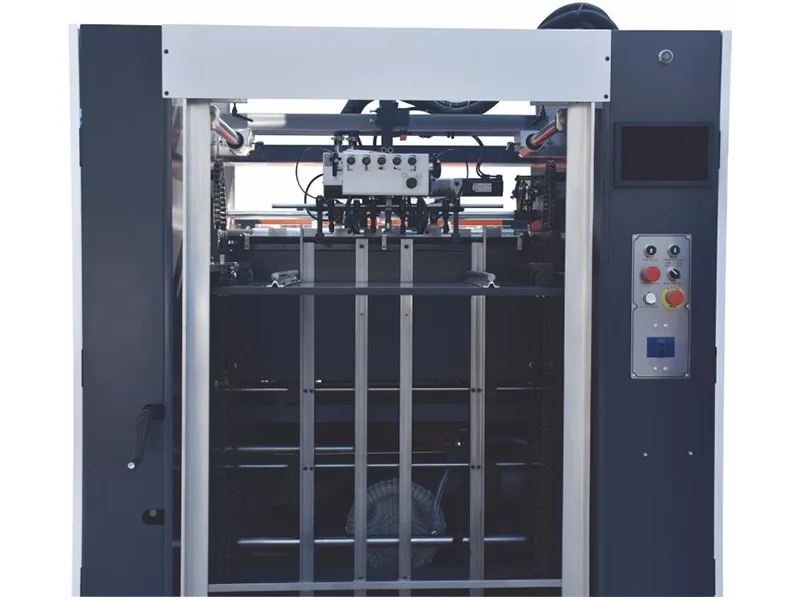

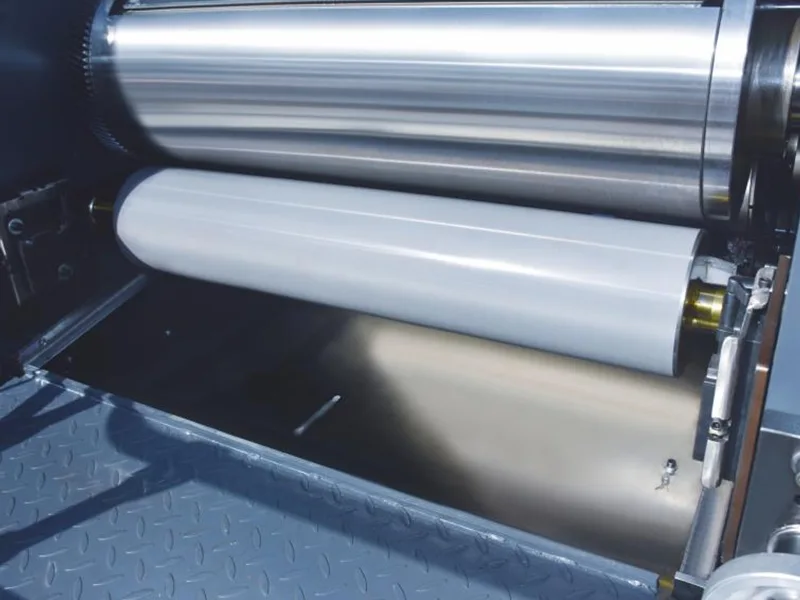

2. Coating host

- Coating speed up to 6000-9000sheets/hour.

- Using a large diameter imprint drum, drum by dynamic balance, coating oil film flat.Double shaft oil transfer, scraper, simple and reliable control of oil.

- Coating drum adopts screw fixed clamping device, which is simple and durable.

- Roller forward and backward oil transfer structure, easy conversion, flexible thickness adjustment.

The FHSGJ-760 1050 is available with optional ceramic anilox rollers and doctor blades.

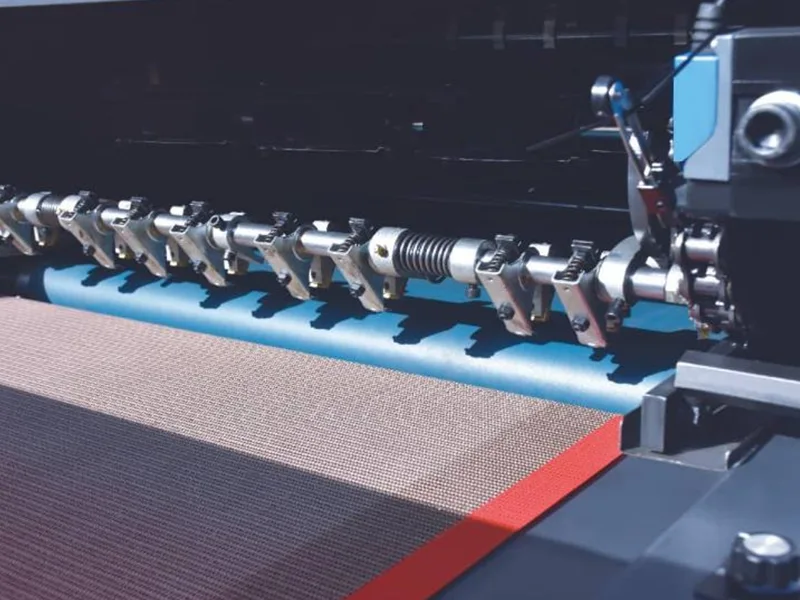

3. UV drying equipment(UV dryer + IR dryer)Major upgrade with optional UV LED lamps

- UV drying equipment adopts three UV mercury lamps, which can quickly solidify UV varnish.

- Equipped with full/half light conversion.

- Built-in automatic temperature control and electronic abnormal jumping.

- Water - based IR drying equipment, can dry water - based varnish.

-LED lamps use a low-temperature curing process to ensure paper quality and allow the varnish to cool faster, providing you with a higher quality experience!

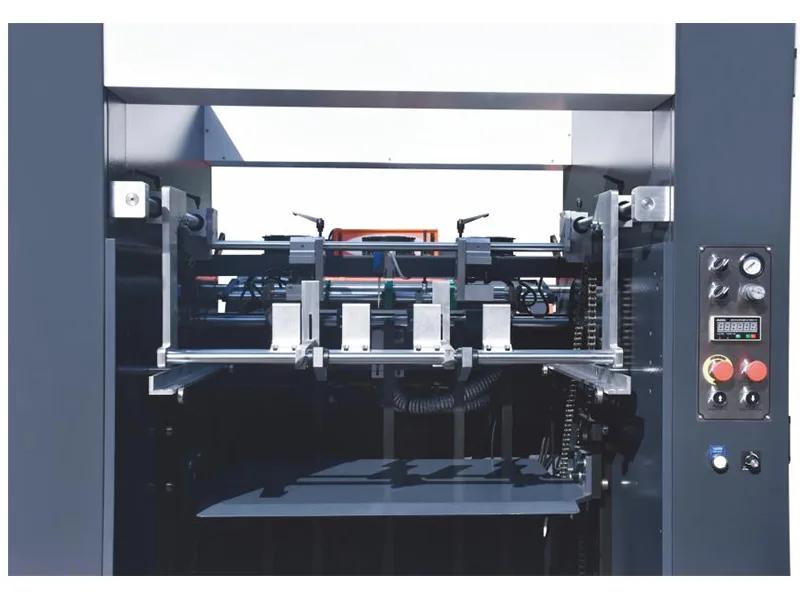

4. Automatic paper stacker

- The paper stacker is equipped with an automatic paper loading platform.

- Photoelectric pneumatic two-sided paper leveller and strong paper flat and slow;Intermediate device to prevent the release of thick paper inertia; Medium range to ensure smooth and neat paper receiving.

- Equipped with cooling fan and optional cooling air conditioning.

- Abnormal status indicator light and safety detection system to quickly inform the staff of abnormal status.

5. Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

【1】 Automatic feeder (no shaft drive motor)

|

Pallet Motor |

1set |

|

Dual seat vacuum suction pump |

1set |

|

Delivering rubber roller |

2 set |

|

Embossing steel roller |

1pc |

|

Feeder Belt |

4pcs |

|

Pressure frame with aluminum rod |

1 set |

|

Laminating roll |

12set |

|

feeder |

1set |

【2】Coating system (UV oil/Water-based glossy oil)

|

(1) Power motor |

1 set |

|

(2) Coating rubber roller |

1 pc |

|

(3) Coatingsteelroller |

1 pc |

|

(4) Upswing |

2pcs |

|

(5) Steel roll for oil control |

1pc |

|

(6) thickness regulator |

2pcs |

|

(7) Adjustable handwheel |

4pcs |

|

(8) Oil pump |

1 set |

|

(9) Stainless oil drum |

1 pc |

|

(10) Blade seat |

1 set |

|

(11) Recycle system |

1 set |

|

(12) Paper tooth row |

5pcs |

|

(13) Main machine belts |

1set |

|

(14) Paper blower |

1set |

|

(15) Counter motor |

1set |

【3】IR drying conveyor(UV dryer + IR dryer)

|

(1) IR Drying system |

1 set |

|

(2) UV control box |

1 set |

|

(3) UV lamp |

3 pcs |

|

(4) Wind chamber |

1 pc |

|

(5) Suction windmill belt |

2pcs |

|

(6) Light box cooling windmill |

1 pc |

|

(7) UV circuit controlbox |

1 pc |

|

(8) Belt |

1 pc |

|

(9) Belt motor |

1 pc |

|

(1) Pallet motor |

1 set |

|

(2) Tidy paper aluminum plate(One left、One right) |

2 pcs |

|

(3) Tidy paper cylinder |

2 pcs |

(1) FHSGJ-760 Full Automatic high-speed full/spot Varnish Machine Configuration List

|

No. |

Matrl name |

Brand |

|

1 |

Master switch |

Schneider |

|

2 |

Contactor |

Schneider |

|

3 |

Inverter circuit breaker |

Schneider |

|

4 |

Touchscreen |

Taiwan Wei Lun |

|

5 |

Inverter |

Inovance |

|

6 |

PLC |

Delta |

|

7 |

Relays |

Omron |

|

8 |

Bottom switch |

Schneider |

|

9 |

Terminals |

Vedmini |

|

10 |

Button operation |

Taiwan Devadatta |

|

11 |

Counter |

Taiwan Yangming |

|

12 |

Control paper align fiber |

Omron |

|

13 |

Proximity switchs |

Omron |

|

14 |

Control Circuit wires |

Man Hing |

(2)

|

Made by Taiwan,smooth transmission, precision, small vibration, low noise, durability |

|

|

The cylinder and solenoid valve are both use Air TAC |

|

|

Belt |

Italy SAMLA and Japan NIKO |

|

Temperature control system |

Hibek |

|

Chain |

TYC |

|

Bearing |

Japan NHK |

(3) FHSGJ-760 Full Automatic high-speed full/spot Varnish Machine Spared parts

|

NO. |

Description |

Specification |

Qty |

Unit |

NO. |

Description |

Qty |

|

1 |

Coating rubber roller |

¢137.6*1473 |

1 |

pc |

10 |

“-” Screw driver |

1 set |

|

2 |

Plastic scraper |

2*38*1350 |

5 |

pcs |

11 |

open spanner |

1 set |

|

3 |

Wedge woods |

|

4 |

set |

12 |

6T spanner |

1 set |

|

4 |

Anchoring |

M10*60 |

16 |

pcs |

13 |

Tool box |

1 set |

|

5 |

Anchoring |

M8*50 |

6 |

pcs |

14 |

Adjustable spanner |

1 set |

|

6 |

Special Chain knot |

1” |

2 |

pcs |

15 |

Foot gasket |

1 set |

|

7 |

Electrical cable ties |

5*200 |

10 |

pcs |

16 |

Conveyor shelf special foot gasket |

1 set |

|

8 |

Suckers |

|

10 |

pcs |

17 |

Coating machine special foot gasket |

1 set |

|

9 |

“+”Screw driver |

|

1 |

set |

|

|

|

Parameters are subject to change without prior notice, and the actual product shall prevail.

Full Automatic high-speed Full/spot Varnish Machine

(1) Auto feeding

1.Adopt high-speed offset press feeder (9000 sheets/hour) to ensure fast and stable operation

2.Paper photoelectric control, automatic lifting

3.Double protection feeder lifting safety

4.Using the latest paper stacker design, the entire tray can be pushed in, and the tray can be pushed in directly after printing, without manual paper sorting. Pre-stacker can also be used. two-way choice. Greatly save paper time and reduce the labor intensity of operators.

5.Dual-sheet detector

6.Oil-free vacuum pump

7.We've added a feature that allows the machine to adjust the paper's varnishing position using the front and side guides without disassembling the printing board when the paper's position is inaccurate.

8.A new monitoring screen has been added at the feeder, allowing users to see the paper collection status at the paper collection station without needing to move around.

(2) Coating section

2 Coating host

1. Blanket coating: fine and even.

2. Toothed paper feed: no paper roll, smooth high-speed paper feeding.

3. Imported material metering rollers, adjustable oil thickness in both forward and reverse rotation.

4. Main unit wall panel: integral HT200 casting, 80mm thick.

5. Reinforced HT200 casting base, stable high-speed operation, durable bearings.

6. Large diameter impression roller, dynamically balanced for even oil coating.

7. Missing sheet and misalignment detection to ensure registration accuracy.

8. Quick clamping plate.

9. Dual oil pump design for easier cleaning.

10. Oil pan and doctor blade are Teflon coated, non-stick.

- Coating speed up to 6000-9000sheets/hour.

- Using a large diameter imprint drum, drum by dynamic balance, coating oil film flat.Double shaft oil transfer, scraper, simple and reliable control of oil.

- Coating drum adopts screw fixed clamping device, which is simple and durable.

- Roller forward and backward oil transfer structure, easy conversion, flexible thickness adjustment.

- Optional ceramic anilox roller and cavity scraper or ordinary scraper.

New features:To make it easier for customers to change printing board, we have upgraded this feature to achieve a one-step fit.

The FHSGJ-760 1050 is available with optional ceramic anilox rollers and doctor blades.

(3) IR Drying and UV Curing System

3. UV drying equipment(UV dryer + IR dryer)Major upgrade with optional UV LED lamps

- UV drying equipment adopts three UV mercury lamps, which can quickly solidify UV varnish.

- Equipped with full/half light conversion.

- Built-in automatic temperature control and electronic abnormal jumping.

- Water - based IR drying equipment, can dry water - based varnish.

- The oven is equipped with a temperature sensor, and a safety wire is installed under the lampshade to prevent paper from floating and the lamp from catching fire.

- The oven has an automatic lifting function, is fire-proof, and allows for easy lamp replacement.

- Teflon conveyor belt with an automatic deviation correction system.

- Full-process suction paper feeding and exhaust ventilation.

- Fan cooling and paper skipping device.

- LED lamps use a low-temperature curing process to ensure paper quality and allow the varnish to cool faster, providing you with a higher quality experience!

(4) Automatic delivery system

5. Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

1.Paper photoelectric control, automatic lifting

2.Double protection feeder lifting safety

3.Equipped with pneumatic paper flap function, you can set the number and time of the paper beat to ensure neatness

4.Disorderly paper automatic lowering function

5.Matches a paper jam detection system to achieve intelligent deceleration.