- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

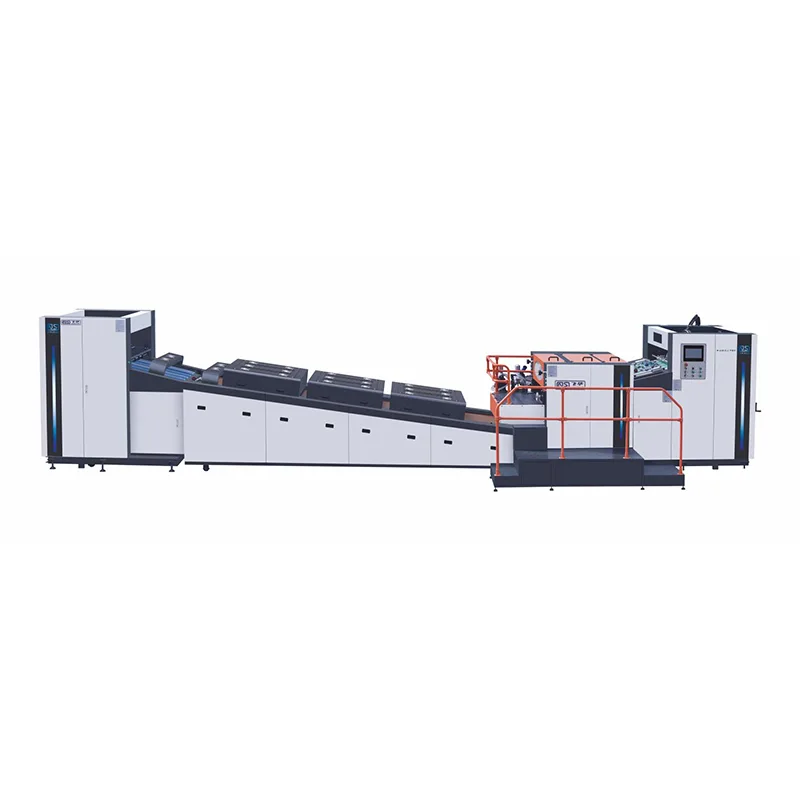

Spot UV Varnish Coating Machine

Send Inquiry PDF DownLoad

The Spot UV Varnish Machine is a cutting-edge device tailored for digital printing applications, offering both full and spot coating options with glossy, matte, and UV oils. This machine enhances the visual appeal and durability of printed materials, making it a valuable asset for businesses looking to elevate their marketing materials, book covers, packaging, and promotional items. Its versatility and precision allow for customized, high-quality finishes that meet specific aesthetic and functional requirements.

Our company is renowned for its strong industry reputation and excellent corporate credentials. We offer significant advantages in freight, delivery times, quality control, and pricing. These strengths have enabled us to export our products to over 40 countries worldwide. Our commitment to maintaining high standards and providing competitive prices has earned us the trust of our global customers, ensuring reliable and efficient service in every aspect of our operations.

Packaging

FHSGJ-1050/1450 Spot UV Varnish Coating Machine

1.Automatic paper feeder

• High reliability is adopted for fast and smooth paper feeding.

• Equipped with sensitive electromechanical double-tension detector and foreign body baffle, the machine will stop immediately if abnormal.

• Accurate and reliable front gauge and side gauge.

• Dual servo Feida, accurate positioning without the need for position adjustment.

• High platform paper feeding,high efficiency.

2.Coating host

Coating speed reaches up to 6000-9000 sheets per hour.

Utilizes a large diameter imprint drum with dynamic balancing for a smooth oil film. Features double shaft oil transfer and a scraper for simple, reliable oil control.

The coating drum uses a screw-fixed clamping device, ensuring simplicity and durability.

Roller design allows for easy oil transfer conversion and flexible thickness adjustment.

Optional ceramic anilox roller with cavity scraper or standard scraper available.

3. UV drying equipment(UV dryer +IR dryer)

• UV drying equipment adopts three UV mercury lamps, which can quickly solidify UVvarnish.

• Equipped with full/half light conversion.

• Built-in automatic temperature control and electronic abnormal jumping.

• Water -based IR drying equipment, can dry water - based varnish.

4.Automatic paper stacker

The paper stacker has an automatic loading platform.

It features a photoelectric pneumatic two-sided paper leveler for strong, flat, and slow paper leveling; an intermediate device to prevent thick paper inertia release; and a medium range to ensure smooth and neat paper receiving.

The stacker includes a cooling fan and an optional cooling air conditioning system.

An abnormal status indicator light and a safety detection system quickly inform staff of any issues.

5.Automatic control

The motor uses frequency conversion for speed regulation, ensuring safety and reliability.

The entire machine is controlled by a PLC programmable system, making it easy to operate and maintain.

All cables are connected with quick connectors, simplifying installation.

The machine features intelligent automatic board changing and paper receiving functions.

6 uv curing and cooling system

UV curing is a process that uses ultraviolet (UV) light to cure or dry coatings, inks, adhesives, and other materials. During UV curing, the UV light activates photoinitiators in the material, triggering a chemical reaction that causes the material to quickly harden. This process is commonly used in printing, coating, and electronics manufacturing because it offers a fast, efficient, and environmentally friendly solution that significantly improves production efficiency and product quality. In a UV spot coating machine, the cooling system prevents overheating by dissipating heat generated during the UV curing process. This ensures consistent performance and extends the machine's lifespan.

Main configuration and features

|

Model |

FHSGJ-1050 |

FHSGJ-1450 |

|

Max.Sheet Size |

730*1050mm |

1100*1450mm |

|

Min.Sheet Size |

310*410mm |

310*410mm |

|

Max varnishing size |

720*1040mm |

1100*1450mm |

|

Glazing overprint accuracy |

±0.2mm |

±0.2mm |

|

Laminating speed |

9000sheet/hour |

6000sheet/hour |

|

UV coating thinkness |

0.06-0.60mm |

0.06-0.60mm |

|

Sheet thinkness |

80-500gsm |

80-500gsm |

|

Total Power |

38kw |

45kw |

|

Total weight |

9000kg |

10000kg |

|

Overall Dimensions |

10630x2260x2100mm |

11000x2725x2100mm |

Note: The working speed varies depending on the material, size, thickness, color, and quality requirements of the printed material.