- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Automatic Double Head Anilox Roller UV Coating Machine

Send Inquiry PDF DownLoad

Automatic double head anilox roller uv coating machine is an innovative and safe solution to enabledwater base coating and soft touch coating of paper. NEW STAR is a global manufacturer and exporter of Automatic double head anilox roller uv coating machine. In China, you can customize your needs to find the most suitable coating machines with best price.

Automatic double head anilox roller uv coating machine

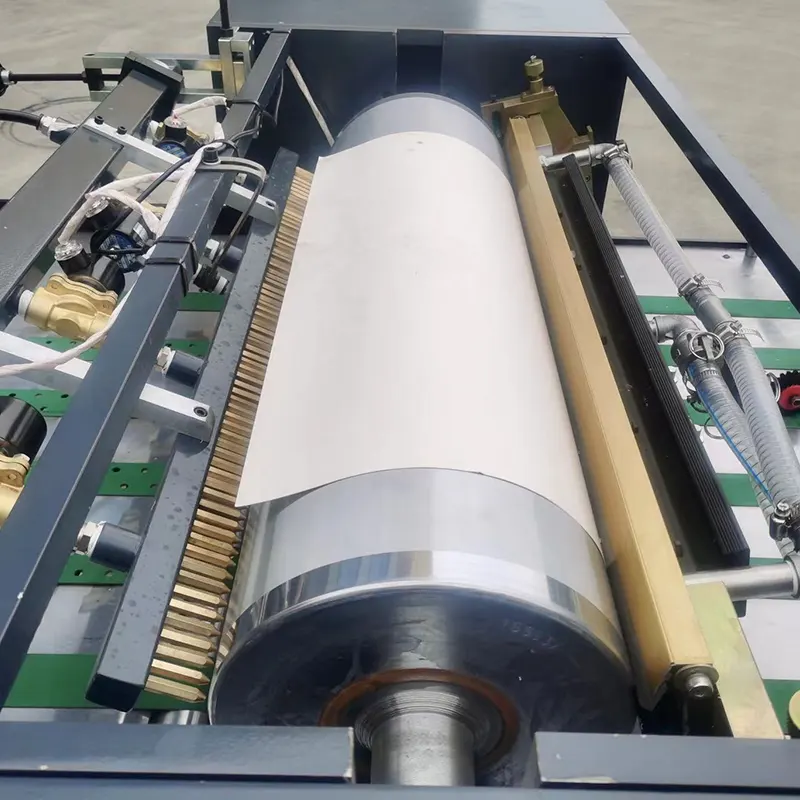

SGUV-800/1200 Automatic double head anilox roller uv coating machine is the first domestic product developed by Feihua, which subverts the traditional rubber roller coating.

The latest anilox coating process: completely solve the phenomenon of orange peel and grain!

Product Parameter (Specification)

|

Model |

SGUV-800 |

SGUV-1200 |

|

Max.Sheet Size |

820*1000mm |

1200*1000mm |

|

Min.Sheet Size |

270*270mm |

300*300mm |

|

Sheet Weight |

250~500g/m2 |

250~500g/m2 |

|

Sheet Weight |

128~500g/m2 |

128~500g/m2 |

|

Speed |

5~100m/min |

5~100m/min |

|

Speed |

5~60m/min |

5~60m/min |

|

Power |

45Kw |

50Kw |

|

UV Lamp |

3pcsx8Kw |

3pcsx9.75Kw |

|

IR Lamp |

18pcsx1.5Kw |

18pcsx1.5Kw |

|

Paper feed heigh |

1100 |

1100 |

|

Paper stack height |

1050 |

1050 |

|

Weight |

6000kg |

65000kg |

|

Dimension |

16500x1850x20000mm |

16500x2050x2000mm |

Product Feature And Application

Applicable for Solve high-end quality fine products: water-based oil, soft touch oil, anti-scratch oil, film replacement oil, etc.

1: Large diameter anilox roller direct coating, no need to transfer rubber roller, can ensure the thickness of the oil on the paper, even without orange peel

2: The closed scraper is used to circulate the oil inside the oil circuit without outflow of oil, which can effectively reduce oil loss and volatilization.

3: The upper and lower rollers are driven by independent motors, without mechanical gaps, which can ensure no streaks in coating.

4: The pressing of the rollers is controlled by servo motors, the thickness of the gap is directly set on the touch screen, and the gap is controlled by the servo motor, which makes the control more accurate and the operation easier!

5: High level of intelligence, one-key start acceleration, more convenient and efficient than traditional segmented control!

6: The shaft head is 55mm large, which is more stable and firmer than the traditional 35mm under high speed, without deformation, and good coating effect!

Product Details

1. Automatic paper feeding section

The paper feeder is an important part of the coating machine. The function of the paper feeder is to automatically, accurately, steadily and periodically separate the sheets one by one, and continuously send them to the regular positioning parts.

The paper feeding method of this machine is continuous paper feeding, which has the advantages of high automation, compact structure, good performance, convenient operation, accurate paper feeding and high precision. The main components of the paper feeder are the paper feed bridge, the paper feed head, the stacking table, the lifting system and the transmission system.

Adopt oil-free vacuum air pump suction system

(2) High-speed offset press feeder (12000 sheets/hour) to ensure fast and stable operation

(3) Frequency conversion speed control paper feeding

(4) The paper feeding table of the production line is positioned and conveyed by vacuum suction to ensure smooth, tidy and stable conveying.

(5) The upper and lower limit protection devices of the feeding table; manual rapid lifting;

(6) The paper feeding table automatically replenishes the paper feeding system;

(7) Attached double sheet controller: double or multiple sheet feeding detection and shutdown system: use the induction of the safety voltage detector to detect double or multiple sheets of paper;

2. Basic oil coating head (with optional air knife device)

The basic head is an important device to ensure that the paper gets a uniform UV layer, which can enhance the adhesion between the ink and the UV varnish.

Basic coating head unit has the following features:

Apply basic oil to fill the capillaries on the paper surface;

Increase the adhesion between UV coating and ink; reduce the penetration of the coating to maintain the pure whiteness of the paper;

Save the consumption of high-grade oil products such as expensive UV oil, touch oil, and film-replacing oil;

Detachable lower scraper, easy to clean and change the blade, and scrape more cleanly

The main drive system adopts synchronous belt drive, double bearing pressure-resistant design, precise and durable

Roll paper failure, automatic stop, automatic alarm.

Castings are processed in one piece, with strong rigidity, stability and durability!

Equipped with highly sensitive air knife system (optional) suitable for both thick paper and thin paper coating;

3. IR Curing System

The water-based infrared dryer means that when infrared rays are radiated to the surface of the coating, a part of it is reflected by the surface of the coating, and the rest enters the coating. For thermal energy, the temperature of the coating is increased, which has the effect of accelerating drying.

(1) It can be used for drying after coating with water or solvent, coating liquid, etc.;

(2) Inside the oven is a temperature sensor, when the temperature in the light box reaches the set value, it will maintain a constant temperature;

(3) Cooling fan system, the paper dries quickly and does not stick back;(4) Adopt energy-saving hot air circulation drying method, which saves more electricity;

(5) No gripper vaccum air suction is attached to the paper, and it is stable and does not go crooked, float up, or pile paper;

(6) Teflon conveyor belt: no deformation, no drag, anti-ultraviolet, durable, automatic conveyor belt correction system, stable and no noise;

(7) IR drying consists of 18 lamps divided into 2 groups (or 3 UVs divided into three groups), automatic constant temperature setting, independent temperature control;

(8) There is a safety wire under the lampshade to prevent the paper from floating or the lamp from burning.

(9) Conveyor belt self-extinguishing function to prevent blockage and fire;(10) IR drying system, light drying, not affected by ventilation, can effectively dry the basic oil layer on the surface of the paper, and will not cause the paper to be stretched and deformed by heat;

(11) Blast cooling has the advantages of high air pressure, high air volume control stability, low noise, and automatic operation. Compared with traditional fan ventilation systems, the drying speed is faster and the effect is better.;

The main body of the drying tunnel adopts infrared drying and fan cooling, which has better cooling effect, more power saving and energy saving.

4. Anilox roller coating head (With optional air knife)

The oil coating machine refers to the process of coating the glazing paint on the surface of the printed matter and leveling and drying it.

(1) Surface oil coating host, with highly sensitive air knife system, computer control (optional) suitable for thick paper and thin paper

Dual-purpose coating;

(2) Advanced & safe automatic monitor, shutdown and alarm system for coating roller rolls paper.

(3) Low-speed jog debugging, after processing the roll paper, the paper is ejected;

(4) No gripper vaccum air suction, adhere to paper, not crooked;

(5) Newly developed large-diameter anilox roll direct coating does not require the transfer of the rubber roll, which can ensure the thickness and uniformity of the oil on the paper

(6) Original technology upper and lower rollers are driven by independent motors, without mechanical gaps, which can ensure no streaks in coating.

(7) The closed scraper is used to circulate the oil inside the oil circuit without outflow of oil, which can effectively reduce oil loss and volatilization.

5. Second IR Oven (as point 3)

6. Automatic delivery system

The automatic paper delivery machine is equipped with a fan-cooled paper pressing structure, which can perfectly deliver the paper under the high-speed operation of the machine, ensuring that the paper is delivered neatly.

(1) The belt has low-noise paper delivery, and the upper and lower pressure rails are designed to ensure smooth and smooth delivery.

(2) Vacuum suction paper stabilizer device to keep the paper stable; to avoid curling of thin paper coating,

(3) The delivery table can be raised and lowered manually;

(4) The upper and lower limit protection devices of the delivery table;(5) Automatic lowering device of delivery table, and delivery limit paper stop and alarm system;

(6) Automatic coating paper cumulative count;

(7) Random paper automatic sorting device and programmed control and alarm system;

(8) Using high-speed pneumatic photoelectric single-sheet paper-taking system, the paper is accurate and neat;