- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

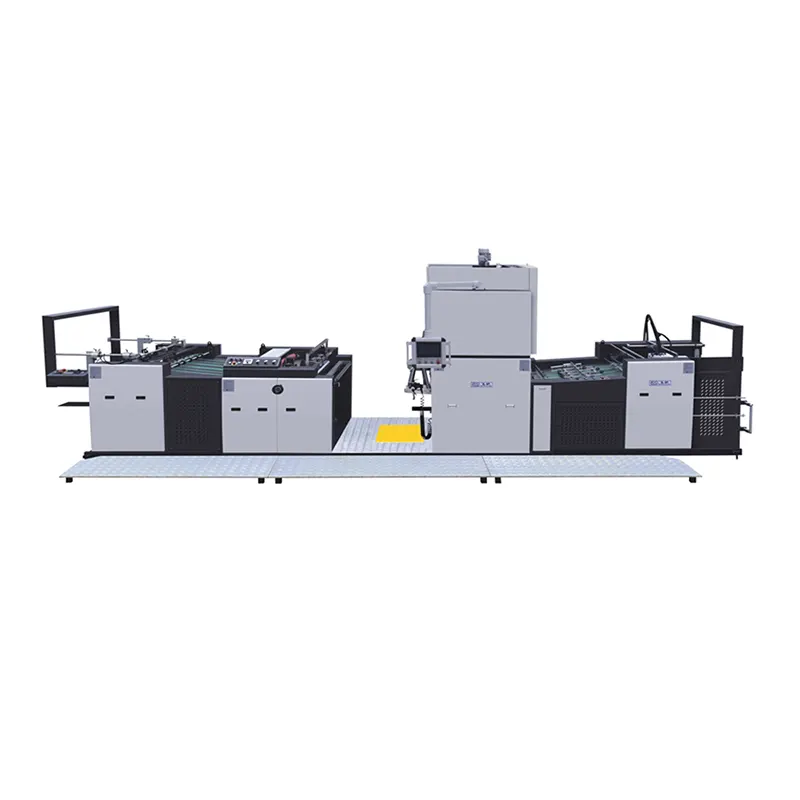

How to choose a laminating machine?

I.What is a laminating machine?

Laminating machines can be classified into the following four major categories based on their working principles.

Hot laminating machines activate heat-sensitive films through heating and are suitable for scenarios that require high bonding strength. However, high temperatures may cause slight deformation to the printed images

Cold laminating machines use pressure-sensitive materials and do not require heating for lamination, making them suitable for temperature-sensitive substrates. However, the drawback is that the cost of consumables is relatively high.

The hot-assisted cold laminating machine combines the advantages of both efficiency and cost, perfectly integrating the strengths of the hot laminating machine and the cold laminating machine. Low-temperature heating can enhance the flexibility of the film and reduce the occurrence of bubbles and silvering.

Liquid laminating machines can achieve protective functions by applying varnish. Compared with others, they have a relatively low cost and are suitable for scenarios such as outdoor billboards.

II.What are the core indicators of quality assessment?

1.Mechanical stability: The stability of key components and structures directly affects the uniformity of film coating. For instance, high-quality rubber rollers are made of silicon materials or high-quality rubber, featuring high elasticity and wear resistance, which can prevent wrinkles or scratches after film coating.

2.Temperature control accuracy: The temperature control of hot laminating machines and heat-assisted cold laminating machines needs to be precise to ±1℃ to ensure the film activation effect. Infrared internal heating technology can enhance heat conduction efficiency and reduce energy consumption.

3.Pressure uniformity: To prevent the possibility of poor adhesion due to insufficient local pressure, the pressure distribution of the laminating roller needs to be verified through a pressure distribution testing system.

4.Electrical Safety: The equipment should be equipped with electrical insulation performance testing and grounding resistance testing functions to ensure operational safety.

III.How to choose the style of laminating machine based on advantages?

The hot laminating machine has high bonding strength and is suitable for printing on substrates such as thick cardboard and metal plates. The cost of consumables is low, making it suitable for products that require high durability, such as packaging boxes and book covers.

The cold laminating machine is easy to operate and does not require preheating. It is suitable for temperature-sensitive materials such as digital prints, such as photos, tenders, menus and other short-run prints.

The hot-assisted cold laminating machine combines the advantages of both hot laminating and cold laminating, reducing the occurrence of bubbles and silvering. Its energy consumption is lower than that of traditional hot laminating machines, and it is widely used in scenarios such as advertising posters and web display boards where efficiency and quality need to be balanced.

The liquid laminating machine has a low cost and can achieve UV protection function. It is suitable for large-area lamination needs such as outdoor billboards, for example, canvas prints, outdoor billboards, etc.

IV.What should be noted when placing an order?

1.Requirement confirmation: Select the machine type based on the substrate type (paper, plastic, metal sheet, etc.), lamination width (such as 720mm, 1020mm, etc.) and production efficiency requirements (such as lamination speed 0-20m/min).

2.Supplier screening: Give priority to manufacturers with CMA/CNAS certifications to ensure that the equipment complies with industry standards. The quality can be verified by checking the test report (such as the adhesive strength of the film coating, electrical safety and other indicators).

3.Contract signing: Clearly define equipment parameters (such as the temperature range for film coating and pressure adjustment methods), delivery date and after-sales service terms (such as warranty period and maintenance response time).

4.Acceptance and Training: After the equipment arrives, tests such as uniformity of film coating and temperature control accuracy need to be conducted, and the manufacturer is required to provide operation training.

V.What developments will there be in the future?

With the increasing environmental protection requirements, the pre-coated laminating machine will become the mainstream in the market due to its compact structure, simple operation, and no need for adhesive coating and drying parts. In addition, the popularization of intelligent technologies (such as PLC control systems and touch screen operation interfaces) has further enhanced the automation level and operational convenience of the equipment.

Simply put, users select the appropriate type of laminating machine based on their actual needs. Wenzhou Feihua Printing Machinery Co., Ltd. has complete qualifications and after-sales service. During the ordering process, only the quality of the equipment needs to be focused on to ensure production efficiency and product quality.