- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What Are the Application Areas of Laminating Machines?

2025-08-07

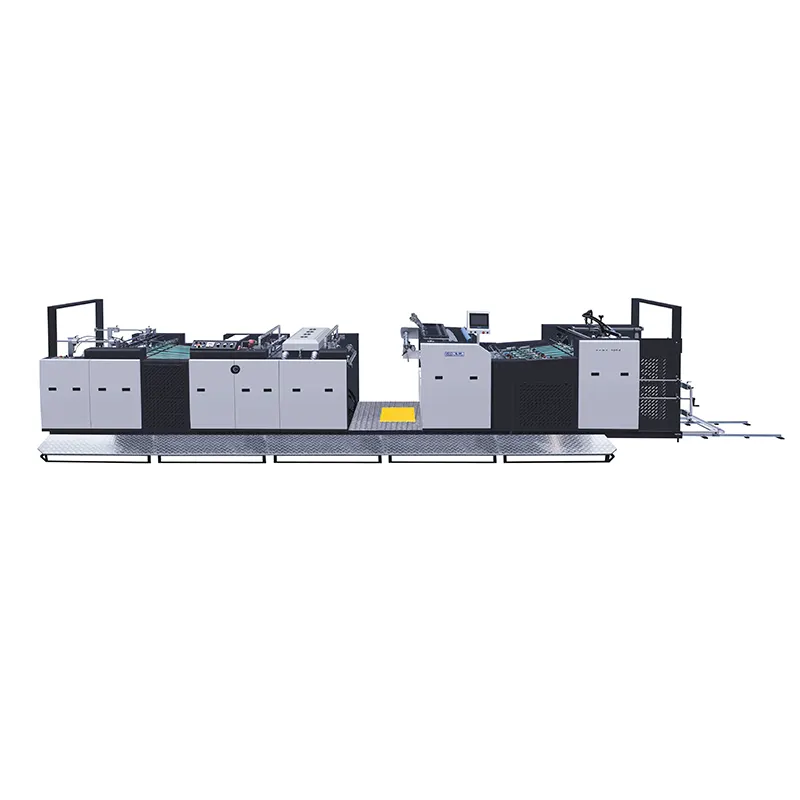

Laminating machines are essential tools in various industries, providing a protective and aesthetic finish to printed materials, packaging, and more. Whether you're in printing, packaging, or manufacturing, understanding the applications and technical specifications of a laminating machine can help you choose the right model for your needs.

Key Applications of Laminating Machines

Printing & Publishing – Enhances durability and appearance of book covers, posters, and brochures.

Packaging Industry – Protects food, pharmaceutical, and retail packaging from moisture and wear.

Education & Stationery – Laminates ID cards, flashcards, and teaching aids for long-term use.

Advertising & Signage – Ensures weather-resistant finishes for banners, billboards, and decals.

Photography & Art – Preserves photos and artwork with a glossy or matte protective layer.

Technical Specifications of Our Laminating Machines

To help you make an informed decision, here are the key parameters of our high-performance laminating machines:

Key Features

Laminating Width: Ranges from 13" to 60" for different project sizes.

Laminating Speed: Adjustable from 1 to 15 meters per minute.

Temperature Control: Precise settings between 50°C to 150°C for various film types.

Thickness Capacity: Handles materials from 80 to 400 microns.

Power Supply: 110V/220V options available for global compatibility.

Comparison Table of Popular Models

| Model | Max Width | Speed (m/min) | Temperature Range | Thickness Range |

|---|---|---|---|---|

| LM-1300 | 13" | 1-5 | 50°C - 120°C | 80-250 microns |

| LM-2500 | 25" | 1-10 | 60°C - 140°C | 100-350 microns |

| LM-4000 | 40" | 1-15 | 70°C - 150°C | 120-400 microns |

Laminating Machine FAQ (Frequently Asked Questions)

Q1: What types of films can be used with a laminating machine?

A: Laminating machines support various films, including glossy, matte, thermal, and cold films. The choice depends on the desired finish and material type. For example, glossy films enhance vibrancy, while matte films reduce glare.

Q2: How do I maintain my laminating machine for optimal performance?

A: Regular cleaning of rollers, proper temperature calibration, and using high-quality films extend machine life. Always follow the manufacturer’s guidelines for lubrication and part replacements.

Q3: Can a laminating machine handle thick materials like cardboard?

A: Yes, but you need a heavy-duty laminator with a higher thickness capacity (300+ microns). Standard machines may struggle, so check specifications before processing rigid materials.

Laminating machines play a crucial role in multiple industries, offering protection and enhancing visual appeal. By selecting the right model based on speed, width, and temperature settings, you can achieve professional-quality results. For further assistance from Wenzhou Feihua Printing Machinery Co., Ltd., consult our product experts to find the best laminating solution for your business.